According to recent reports, TSMC FinFET and Samsung GAA have encountered different but critical bottlenecks in the development of 3nm process technology. TSMC and Samsung will therefore have to postpone the development progress of the 3nm process technology. According to TSMC’s plan, 3nm will complete certification and trial production this year. However, it will be put into mass production in 2022.

As of now, there are reports that Apple already has a good chunk of TSMC’s 3nm process contracts. This means that Apple will be among the first batch of customers for TSMC 3nm process. If there is an extension of the 3nm arrival time, then the 5nm chips will spend more time in the market. At the same time, considering that Intel’s most advanced process is currently 10nm, this also provides an opportunity for Intel’s process to catch up. However, there is still enough time to start production in 2022.

Although the mass production of TSMC and Samsung 3nm process will take place in 2022, we expect TSMC to take the lead. The Taiwanese manufacturer may be up to six months ahead. This front-end Semiconductor Manufacturing Company once claimed that its 3nm process will improve performance by 10% to 15% over the recent 5nm process and that 3nm chips will provide 20% to 25% energy savings.

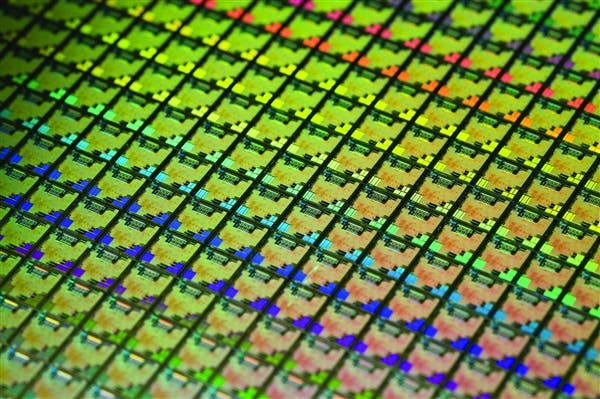

In addition, TSMC Chairman, Liu Deyin, previously stated that TSMC’s revenue this year has continued to record highs, leading the layout of 3nm, and its cumulative investment in Nanke will exceed NT$2 trillion. The goal is to produce 12-inch wafers per month. In contrast, Samsung’s foundry business is preparing to invest US$116 billion in order to catch up with TSMC in the 3nm process.

TSMC will send more than 300 employees to the Arizona plant

Taiwanese chipmaker, TSMC, is currently working on a new chip factory in Arizona, USA. According to TSMC’s schedule, construction will begin next year. The chipmaker is also preparing to dispatch and recruit relevant personnel for the operation of this factory. In a recent interview with TSMC Chairman, Liu Deyin, it was clear that TSMC will dispatch and recruit staff to the US. Liu Deyin said in the interview that they will send more than 300 employees to assist the Arizona factory to start operations. Furthermore, the company will recruit another 300 graduates and engineers with many years of work experience.

The 300 employees dispatched to the Arizona factory will receive a year of full English training so that they can work in the Arizona factory. The employees (both dispatched and recruit) will be R&D engineers, process engineers, equipment engineers, and IT software engineers.

TSMC’s plan to build a factory in the United States first hit the public domain on May 15 this year. The goal is to put this plant into operation in 2024. TSMC will invest $12 billion in this factory from 2021 to 2029. This plant will work on a 5nm process and its monthly production capacity will be 20,000 wafers.

However, the 600 employees currently planned by TSMC is expected to be only the initial number of employees. When announcing the factory plan at that time, TSMC stated that the factory would directly create 1,600 high-tech jobs and indirectly create thousands of other jobs in the semiconductor field.