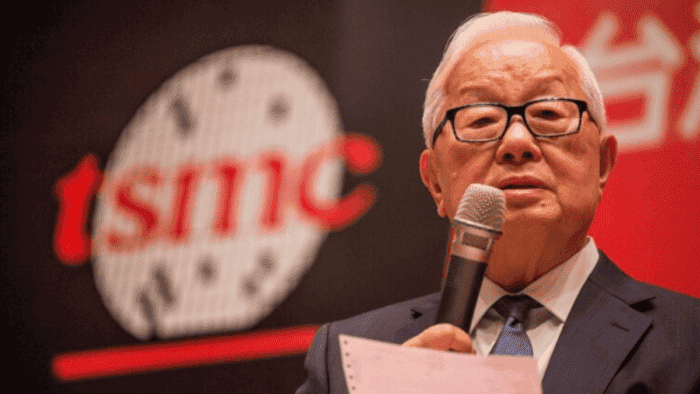

According to the Taiwan Economic Daily, TSMC founder, Zhang Zhongmou (Morris Chang), said in an interview recently that the United States is expensive, wasteful and futile to increase domestic chip production. Simply put, the U.S. is 50% more expensive than Taiwan. It is also much more expensive to carry out production in the U.S. than in China. In this regard, semiconductor industry analyst Lu Xingzhi said that he agrees with the founder of TSMC. However, he does not know if there is a “step that allows TSMC to change its plan.”

Lu Xingzhi points out that the reason why TSMC went to the United States to set up a factory was mainly because it thought that it could get subsidies to reduce some costs before considering it. Therefore, 20,000 5nm mini advanced factories were planned in the early stage. However, all doesn’t seem to be going according to plan as the US government grants official document has not come down. Thus, there may be no subsidies if TMSC wants to expand its production in the future.

The main reason for the change of this is probably the change in government in the U.S. Former president Trump was so interested in the production of high-end chips locally in the U.S. He is the architect of the TSMC – U.S. deal. However, he is no longer in power and the new government seems to have bigger issues to deal with.

TSMC and Sony official collaboration – to commence shipment in 2024

Japan Advanced Semiconductor Manufacturing Company (JASM) is a joint venture between TSMC and Sony. Construction on this company is now ongoing and should be complete in September 2023. The company will officially commence shipment in December 2024. According to the Business Times, the new plant is located in the second raw water industrial complex in Kikuyo-Cho, Kumamoto Prefecture. More than 10 large-scale machineries are available and construction is ongoing.

Regarding the construction of the new factory, JASM President, Yuichi Horita said that the Japanese market has customers with stable demand and many related industrial chain manufacturers. Thus, it has an advantage in the supply chain. In addition, there are excellent human resources to look forward to.

As previously reported, JASM will employ a total of 1,700 employees, including 300 from TSMC and 200 from Sony. JASM was jointly established by TSMC and Sony Semiconductor Solutions (SSS) in November 2021. In February 2022, Denso announced plans to invest $350 million for a more than 10% stake in the foundry.

TSMC claims it would enhance JASM’s capabilities with 12/16nm FinFET process technology. This is in addition to the previous 22/28nm process. TSMC and its partners claim that the monthly production capacity of the Kumamoto fab is 55,000 12-inch wafers. The initial production forecast is 45,000.